When evaluating premium cookware brands like Le Creuset, discerning home chefs often wonder where the magic happens behind the scenes.

Specifically, foodies may be curious where the stainless steel lines hail from if the iconic cast iron still stems from northern France.

As it turns out, Le Creuset operates two main production hubs: the original French foundry focused on enameled cast iron and a newer Portuguese plant dedicated to stainless steel.

Let’s dive in to understand why Le Creuset elected to geographically separate these manufacturing processes and how they uphold consistent quality.

History of Le Creuset

Le Creuset was founded in 1925 in the small northern French town of Fresnoy-le-Grand by two Belgian industrialists, Armand Desaegher and Octave Aubecq.

Prior to founding Le Creuset, Armand Desaegher had invented the process of enameling cast iron earlier in the 1920s as a metallurgist in Belgium.

Seeing commercial potential for quality enameled cast iron cookware, Desaegher partnered with longtime friend Octave Aubecq to form Le Creuset and open the first foundry and factory in Fresnoy-le-Grand.

The first Le Creuset pieces were Dutch ovens or cocottes with a signature vibrant flame-colored orange interior.

This bold and bright orange color then came to distinguish the early Le Creuset brand from the competition.

Though competitors eventually emerged, Le Creuset maintained the dominance and recognition as the first producer of ornamental and functional enameled cast iron cookware.

Over the next century, their offerings would expand across pots, pans, kettles and more while retaining leadership in enameled cast iron.

Le Creuset steadily grew its operations out of the founding factory and foundry in northern France.

Additional buildings were added over ensuing decades to expand production capacity.

By the mid 1900s, international popularity for French cooking meant global demand rose for Le Creuset’s enameled cast iron wares.

Though new colors and shapes were introduced, almost all iron casting and enameling work remained centered in the original northern France headquarters.

Recent decades have seen Le Creuset expand into stainless steel, ceramic, and other cookware lines to diversify beyond enameled cast iron.

These additional cookware offerings joined the mix of pots, pans, baking dishes and accessories to provide a comprehensive selection.

However, each piece of cast iron cookware still passes through the enameling workshop inside the headquarters foundry buildings erected in the 1920s.

Maintaining this original site allows preservation of nearly a century of tradition, technique and expertise unique to Le Creuset cast iron.

Le Creuset Stainless Steel Manufacturing Today

While enameled cast iron production is contained at the long-running foundry in northern France, Le Creuset operates a dedicated facility in Portugal for stainless steel cookware manufacturing.

As with all products, producing Le Creuset stainless steel requires specialized high-quality construction.

To best facilitate those needs for stainless steel, Le Creuset elected to establish and outfit a separate Portuguese workshop explicitly for stainless steel cookery.

Raw stainless steel material sourced from across Europe first enters the Portuguese site to be cut, welded, stamped and molded into Le Creuset cookware pieces.

The multi-stage process begins by cutting sheets of steel into required shapes and sizes using advanced laser and press technology.

Next, steel pieces are joined together through modern welding methods to create solid construction.

During the welding phase, critical design aspects like evenly-sized walls of optimal thickness are closely monitored.

Tri-ply cooking surfaces are sandwiched, with aluminum or copper cores encased by durable stainless exterior and cooking surfaces.

The shaping and welding processes utilize a combination of computer modeling, machine molding and manual finishing.

This achieves an ideal balance of technological precision and hand-crafted final touches.

The welding result is then stamped with the Le Creuset logo and text, signifying the transition to finishing steps.

A team of metalworkers manually carry out extensive polishing, buffing and shine enhancement by hand.

Both interior cooking surfaces and exterior sides are burnished to a flawless mirrored finish.

This last polish and detailing requires a delicate human touch passed down through generations.

Rigorous multi-stage quality control checks follow to inspect for the slightest defects, ensuring only sound product moves forward.

Once the polishing and examination concludes in Portugal, the stainless steel cookware transports to northern France for final touches.

Groups of French artisans fully hand-finish the exteriors and interiors in the French workshop built alongside the enameling foundry.

Using specialized tools and proprietary polishing compounds, they enhance the shine and smooth edges.

The cookware then undergoes one last round of scrutiny from the Quality Control team evaluating properties like flatness, lid fit and more.

Only products meeting stringent standards get approved to ship to Le Creuset’s global customers.

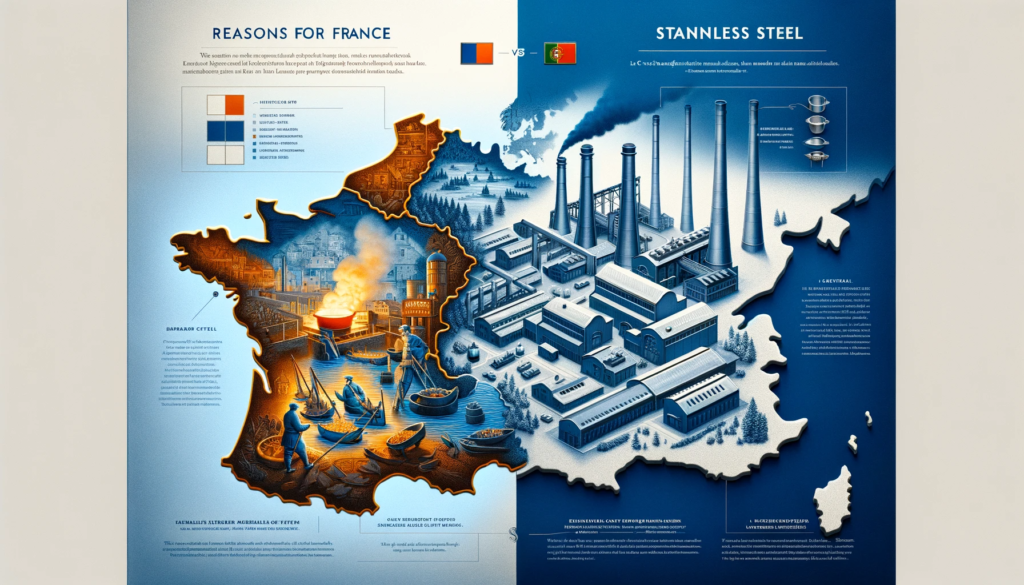

Reasons for Manufacturing Location

The separate manufacturing facilities in northern France and Portugal allow optimized production of enameled cast iron and stainless steel, respectively.

Attempting to produce both lines equally well in one site would likely lead to sacrifices in efficiency or quality.

By keeping the specialized enameled cast iron process fully in France and offloading stainless to Portugal, Le Creuset maximizes the potential of each cookware type.

Relocating enameled cast iron production outside of northern France presents immense challenges Le Creuset concluded simply could not be justified.

The company as founded on the innovations Armand Desaegher pioneered around quality enameled iron.

Every advancement made in close to 100 years of cookware manufacturing occurred in this singular home location.

To replicate the technical tribal knowledge around precision casting, custom enamel mixture and application, specialized production tooling and more would verge on impossible.

Cookware competitors who have attempted to adopt Le Creuset techniques without these capable artisans have failed to achieve product parity.

Furthermore, the symbolic ties between northern France and Le Creuset customer loyalty run quite deep.

As older generations pass down the distinctively colored heirloom pieces spanning years, preserving that magical emotional experience hinges on consistency.

The thought of outsourcing such a core process could undermine long cultivated brand perception.

When customers see “Made In France” on these products, it reinforces the care and craftsmanship in a way foreign production simply cannot.

Le Creuset rightly sees its original French site and team of iron workers as vital brand assets needing safeguarding through continued local operation.

In contrast, Le Creuset stainless steel offered a prime chance to expand globally.

Stainless steel cookware carries no deep connection to legacy production sites.

And Asian facilities in particular have grown adept at efficiently producing stainless goods due to proximity of component materials.

However, Le Creuset opted to keep entire stainless steel supply chain limited within Western Europe – likely for quality assurance reasons.

The decision to situate the operation in Portugal came down to trade advantages around tariffs as well as steel sourcing.

Portugal and Spain lead Europe in stainless steel production, simplifying the supply chain.

So while still distant from historic northern France home, Portugal gave Le Creuset a cross-border European solution to enable excellent stainless capability.

What Sets Le Creuset Stainless Steel Apart

Whether produced in France or Portugal, all Le Creuset lines maintain the same standards customers expect from this premium brand.

Rigorous inspectors across multiple process waypoints continually verify exacting specifications are achieved.

This foundations built during Portuguese fabrication enable the expert French polish and finish artisans to complete their work for flawless results.

While many brands focus solely on superficial shine, Le Creuset stainless steel embodies quality through and through.

The thieves tri-ply construction pioneered by Le Creuset remains the gold standard in stainless steel cookware performance.

The aluminum or copper core rapidly spreads heat for fast, even cooking without irritating hot spots.

Durable stainless steel layers surround the core, providing structural stability and corrosion resistance for longevity akin to cast iron models.

Precision welding joins all the layers securely, preventing deterioration after daily usage across multiple decades.

Matching lids fit tightly to circulate heat and moisture for tender and juicy results.

Riveted stainless handles stay cool while supporting safe transfer between stovetops and ovens up to 500°F.

The mirror-polished cooking surface sears, sautes, fries and more with ease while simplifying post-meal cleanup.

Decorative and functional helper handles supply extra grip as needed for larger stockpots or pans.

These smart elements tailored for cooking success position Le Creuset stainless as an extension of the chef actively creating.

In the never-ending search for cookware obtaining both elite performance and striking visual charm, Le Creuset stainless steel checks all boxes.

Timeless styling in modern brushed finishes dresses up any contemporary kitchen.

Robust construction able to tackle an ambitiously diverse range of recipes makes this metal cookware feel as versatile as worn cast iron.

Supported by Le Creuset’s lifetime warranty and easy replacement parts availability, choosing stainless steel line items gains home cooks outstanding function, form and support through every culinary venture.

Whether sourced from Portugal or France, these handsome longevity-built stainless sets deliver satisfying results daily for years without equal in their class.

Conclusion

In conclusion, while Le Creuset stainless steel cookware carries the same standards of quality as its enameled cast iron, the manufacturing process necessitates separate facilities.

Strategic choices to keep enameled cast iron production in northern France and establish stainless steel fabrication in Portugal allow Le Creuset to optimize operations.

Customers can continue relying on the superb cooking performance Le Creuset promises regardless of the origins of their cookware.