When scanning the bottom of the latest T-fal pan you just bought, you might be wondering—where exactly is this cookware coming from?

From its French roots to today’s Chinese mass production, T-fal cookware strikes a balance between quality and affordability.

Let’s explore the manufacturing origins behind this leading global cookware brand.

Where is T-fal Stainless Steel Cookware Made?

T-fal stainless steel cookware is made primarily in China today, with some premium lines still produced in France where the iconic brand originated.

While French manufacturing persists for high-end offerings, the majority of affordable T-fal cookware for everyday consumers now comes from modern Chinese factories meeting T-fal’s stringent global quality standards.

Below we’ll take a deeper look at how T-fal stainless steel cookware is made both in China and France based on product tier.

History of T-fal

T-fal, known for its innovative non-stick cookware, originated in France in 1956.

The company was founded by Marc Gregoire, a French metallurgist who had developed a non-stick coating for cookware using a material called polytetrafluoroethylene (PTFE), better known today by the brand name Teflon.

Gregoire’s new water-based coating proved remarkably slick and was soon branded under the name Tefal, a portmanteau combining the words Teflon and aluminum, the metal commonly used in cookware.

The new non-stick Tefal cookware was an immediate success when it launched in France in 1956.

Just two years later, in 1968, Tefal was acquired by the large French appliance manufacturer Group SEB.

Under new ownership, Tefal expanded its cookware offerings in Europe throughout the 1960s and 1970s.

When Tefal began selling products in North America in the 1980s, the name was changed to T-fal to match the common shortening of aluminum to “alum.”

Today T-fal sells non-stick and stainless steel cookware globally and is particularly known for pioneering early innovations in non-stick surface coatings and technologies.

T-fal’s Manufacturing Locations

As T-fal has expanded into one of the world’s leading cookware brands, its production facilities have grown as well.

T-fal cookware continues to be produced in some of the company’s original factories in France, but today, the majority of T-fal products are manufactured in China to reduce costs for consumers.

Select T-fal products are also crafted by a network of specialty suppliers located around the world.

France

While much T-fal cookware is now made in China, some pots, pans, and other products are still produced in the company’s home country of France.

In particular, T-fal’s high-end, premium cookware lines targeting professional chefs and cooking enthusiasts continue to be manufactured in France.

Since French labor and production costs are higher than in developing economies like China, keeping these luxury product lines in legacy French factories preserves T-fal’s reputation for quality while allowing niche luxury models to command appropriately elevated prices.

By retaining some cookware production in France alongside its newer Chinese manufacturing centers, T-fal manages to straddle both high and low price points across its range of product offerings.

Items made in France appeal to discerning consumers willing to pay more for cookware still stamped with a “Made in France” mark of quality, while moving most mass market models to Chinese production keeps costs affordable for regular households.

T-fal’s ability to strategically shift manufacturing between locations has allowed it to perfect this balancing act between premium and budget cookware over the last 40 years.

China

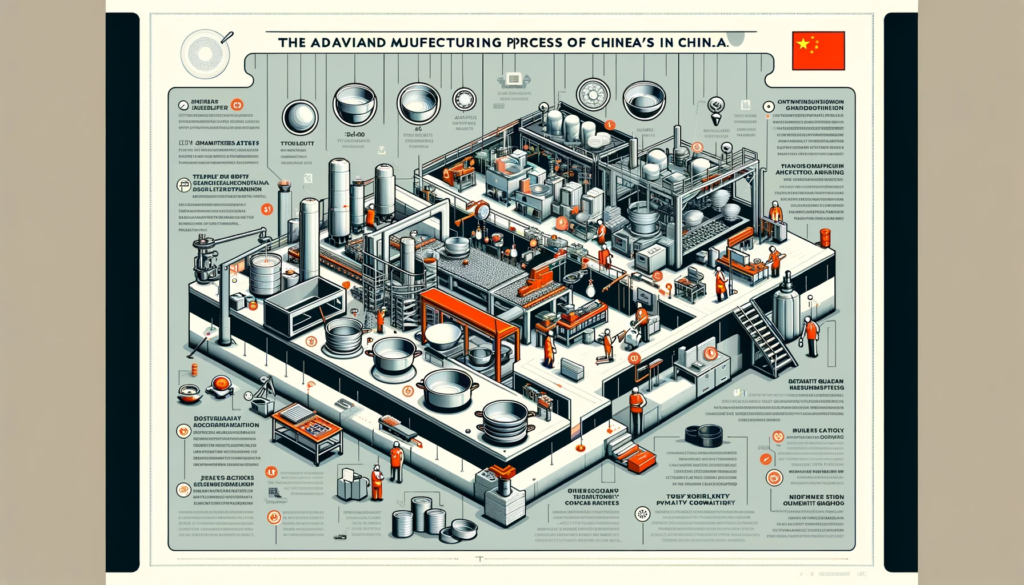

While some T-fal cookware continues to be produced in the company’s original French manufacturing centers, the majority of T-fal products today are made in China.

To reduce manufacturing costs without compromising strict quality control standards, Tefal transitioned most of its cookware production to Chinese factories beginning in the 1990s.

This shift enabled the company to significantly cut consumer prices across entire product categories.

By leveraging China’s large skilled workforce and established national infrastructure for metalworking and cookware manufacturing, T-fal could minimize expenditures while still closely overseeing materials sourcing, product quality, and other facets of Chinese-based manufacturing.

Throughout the 2000s and 2010s, T-fal continued expanding both its network of Chinese manufacturing partners and range of Chinese-made offerings, transitioning even premium product lines like T-fal Professional cookware to factories in China.

While a “Made in China” mark once elicited skepticism among global consumers, T-fal has demonstrated over decades of working in China that Chinese factories are fully capable of meeting the brand’s stringent material and performance benchmarks.

By investing heavily in training programs and quality assurance processes for its Chinese manufacturing sites, T-fal has shifted most of its current output to Asia without sacrificing reliability or longevity.

For budget-conscious consumers unwilling or unable to pay premium prices, T-fal’s Chinese-made cookware delivers impressive durability and functionality at accessible price points.

Select Products Made in Other Countries

Beyond T-fal’s core manufacturing operations in France and China, the brand also sources select products from specialty facilities located around the world.

Although most mass market T-fal cookware is currently made in China, niche product lines may be produced elsewhere to leverage unique local skills, resources, or manufacturing cost advantages in a given region.

For example, some specialty T-fal cookware like woks and tagines may be made in factories based in Turkey, Thailand, or other countries.

Small batches of regionally popular products are occasionally manufactured in localized factories expressly equipped to handle niche fabrication techniques.

While the vast majority of T-fal cookware ultimately funnels out worldwide from the company’s

French headquarters and Chinese manufacturing centers, contract production in specialty facilities sprinkled globally gives T-fal additional flexibility responding to a perpetually shifting consumer cookware landscape.

Quality Control Across Manufacturing Locations

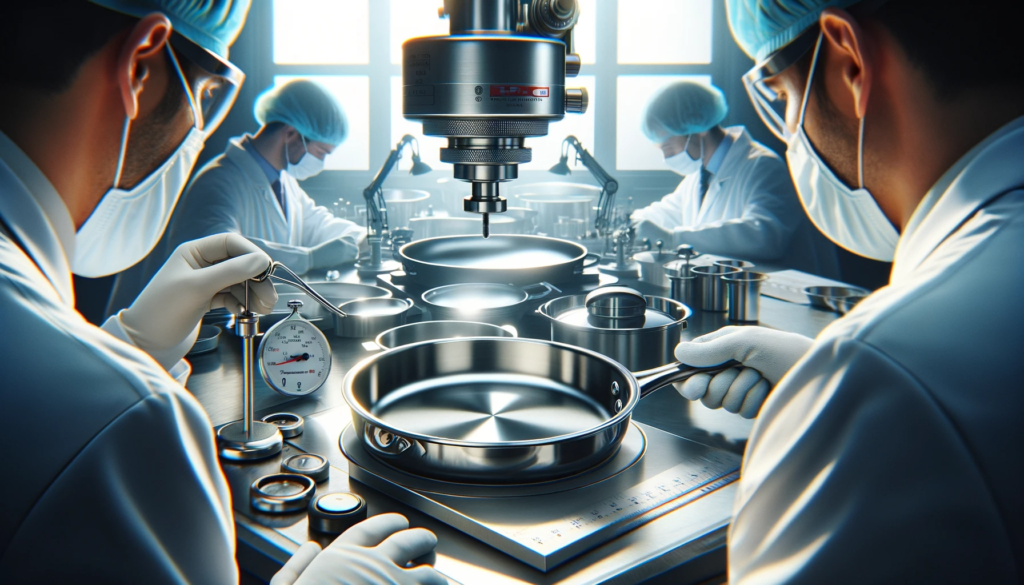

Importantly, no matter where T-fal cookware products originate geographically, the same stringent quality control and performance testing applies universally.

T-fal proudly stands behind lifetime guarantees on most product lines regardless of where each item was manufactured.

The origin marking on a pan’s base may read “Made in France” or “Made in China,” but T-fal’s reputation for reliable, durable everyday cookware remains intact across its entire catalog.

By investing heavily in standardized training, operating procedures, and quality assurance processes within each of its global production facilities, T-fal has largely eliminated any durability or longevity differences between geographically dispersed factories.

Local T-fal quality engineers rigorously vet all incoming raw materials, supervise manufacturing workflows, triple-check finished products, and regularly submit samples for additional quality auditing before products ever reach retail shelves.

This exhaustive quality control regimen ensures that a Chinese-made frying pan meets the same performance thresholds during testing as a French-made counterpart.

While budget-friendly cookware lines made exclusively in China may lack some premium add-ons or flashy aesthetics reserved for high-end ranges, all T-fal cookware uniformly delivers on fundamental promises of long-lasting performance suitable for years of regular stovetop cooking.

Even T-fal’s flagship Professional 10-piece cookware set representing the pinnacle of the brand’s durable, ergonomic design is now Chinese-made after transitioning from France a few years ago.

Manufacturing refinements and process improvements at T-fal’s top-tier factories in China have made geographical divisions between French and Chinese factories mostly obsolete in terms of quality, lifespan, cooking performance, and other metrics that matter most to home cooks.

Of course, discerning cooks comparing specifications may still detect hallmarks of French craftsmanship permeating specialty French-made T-fal offerings crafted expressly for chefs and demanding cookware enthusiasts.

But for average households simply seeking reliable, hassle-free T-fal cookware suitable for daily meal preparation, Chinese-made products deliver everything needed for years of cooking enjoyment without premium French prices.

Thanks to T-fal’s expansive on-the-ground manufacturing expertise in China matched by exhaustive quality testing, Chinese-made pans perform admirably despite export logistics stretching halfway around the world back to T-fal’s French headquarters.

Conclusion

As one of the world’s leading cookware brands, T-fal has carefully balanced keeping premium manufacturing capabilities in France while expanding mass market production in China over recent decades.

This blend of legacy French craftsmanship and disciplined Chinese efficiency enables T-fal to offer durable, reliable cookware accessible to all budgets.

Thanks to intensive quality control practices benchmarking performance across all factories, customers can shop T-fal’s catalog with confidence knowing products deliver consistent quality for years whether made in Europe or Asia.

When searching for long-lasting cookware combining legacy French innovation with global materials and manufacturing expertise, T-fal cookware is clearly where savvy shoppers should start.