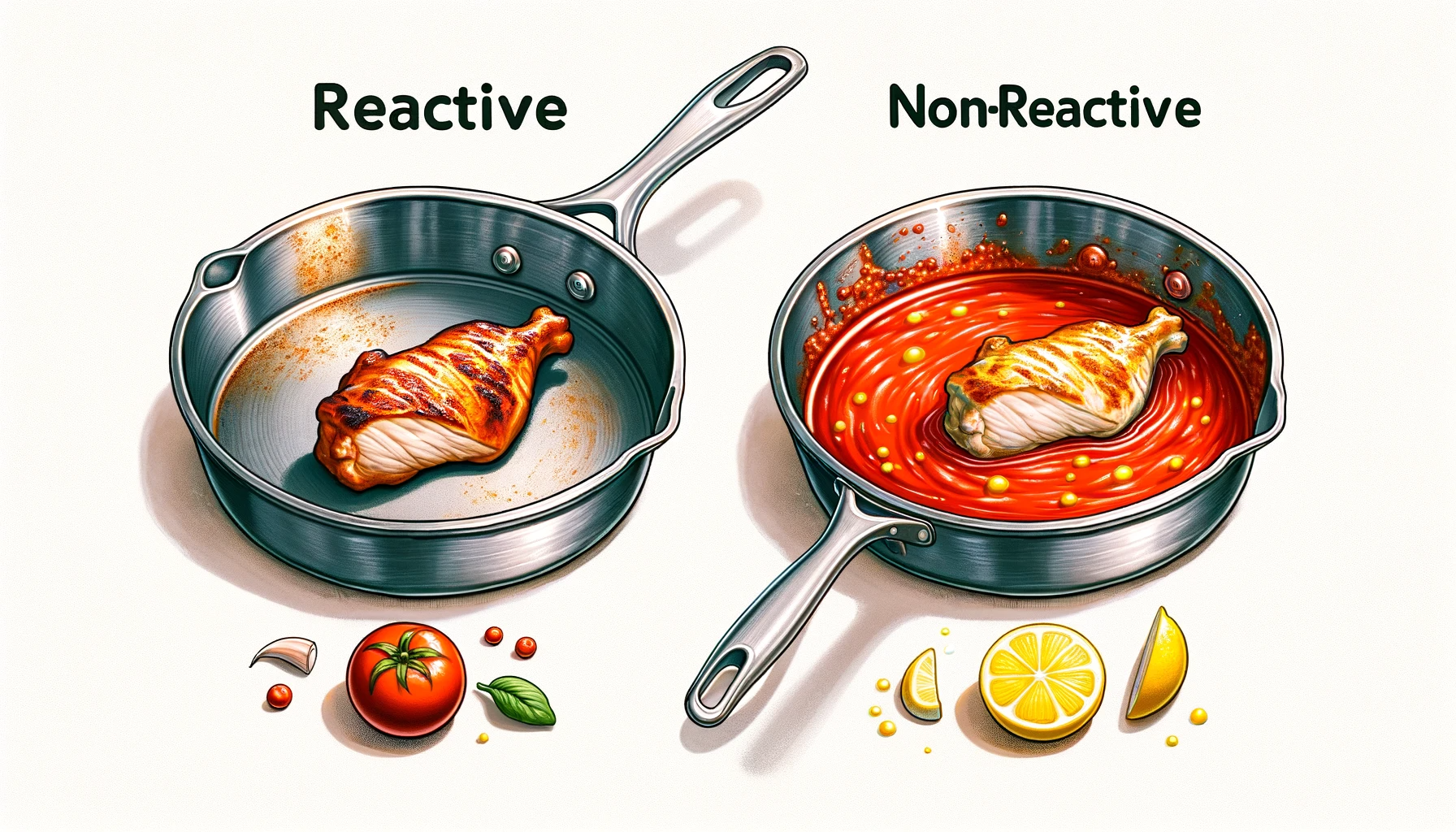

Have you ever noticed a metallic taste after cooking tomato sauce or lemon chicken in stainless steel pans? This reaction shows the cookware is made of reactive stainless steel.

The composition differences between reactive and nonreactive stainless steel impact taste, durability, ease of maintenance and price when it comes to cookware.

Let’s dive into understanding reactive versus nonreactive stainless steel to determine the better choice for your kitchen.

What’s the Difference Between Reactive and Nonreactive Stainless Steel Cookware?

The key difference lies in metal composition.

Reactive stainless steel contains more iron, which can transfer into food and corrode over time with acidic ingredients.

Nonreactive stainless steel has higher chromium and nickel content, preventing metal leaching or corrosion by locking metals in better.

In essence, reactive stainless steel pans will react with acids during cooking, while nonreactive pans resist this reaction.

We will explore this difference in depth in terms of impacts on taste, durability, care and price further below.

What is Stainless Steel?

Stainless steel is an alloy, or mixture, of steel with other elements like chromium, nickel, molybdenum, titanium, copper, and carbon.

The chromium content makes stainless steel resistant to staining, pitting, and rusting.

Stainless steel is valued in cookware for its durability, ease of cleaning, resistance to corrosion, and heat conduction.

The steel gives strength and durability, while the chromium provides the “stainless”, rust-resistant finish.

There are many grades of stainless steel, which denote the quality, durability, and composition.

The grading systems vary by country and manufacturer.

Some focus on the steel-to-chromium ratio, while others denote the presence of other metals like nickel and molybdenum.

No matter the grading convention, stainless steel for cookware always contains iron, chromium, and carbon.

The two main categorizations of stainless steel cookware are “reactive” and “nonreactive.” Whether stainless steel cookware is reactive or nonreactive depends on its exact alloy composition and grade.

Reactive stainless steel contains iron in its alloy mix, which can react with acidic foods during cooking.

Nonreactive varieties have less iron and more chromium and nickel to prevent this reaction.

Reactive vs Nonreactive Stainless Steel

Reactive stainless steel contains a substantial amount of iron in its alloy composition.

The iron is essential for providing strength, hardness, and durability.

However, iron can react with acidic food ingredients like tomatoes, vinegar, wine, and many fruits.

This reactivity causes the iron to leach from the cookware into the food in small amounts.

Reactive stainless steel typically has an alloy composition containing anywhere from 50% to 70% iron.

It has a lower chromium content compared to nonreactive stainless steel, often in the 16% to 18% range.

Other metals like nickel may be present in very small percentages.

Overall, there is enough iron exposure to cause reactivity.

Nonreactive stainless steel, in contrast, flips the composition script.

It contains a higher percentage of chromium, in the 18% to 30% range depending on grade.

It also has more nickel, from 8% to 20% depending on grade.

The chromium, and in some cases the nickel, strengthens the anti-corrosive abilities so these metals stay locked in better and do not leach into food.

With less iron content, nonreactive stainless steel will not react with acidic ingredients.

How Reactivity Impacts Cooking

When cooking with reactive stainless steel, there is a risk of the iron leaching into acidic foods.

For example, if cooking a tomato sauce for several hours, enough iron may transfer to lend an unpleasant metallic taste.

If onions or garlic are cooked in reactive stainless steel cookware for too long, they can also take on metallic undertones.

Any recipe using vinegar, citrus, tomatoes or mustard can showcase this reactivity.

Additionally, reactive stainless steel is prone to corrosion over time after repeat exposure to moisture and acids.

Even if you are diligent about cleaning after cooking acidic foods, microscopic bits of food, grease and the acidic ingredients themselves leave behind an invisible film over months and years of use.

This eventually eats away at the pan’s surface, causing pitting and corrosion that requires more frequent replacement.

Nonreactive stainless steel prevents metallic leaching during the cooking process.

Tomatoes simmered for hours, vinegar reductions, pan sauces deglazed with wine or citrus, and other acidic ingredient-heavy dishes will never take on a metallic flavor when cooked in nonreactive stainless steel.

The metals in the cookware will not transfer or change the taste profile at all.

Additionally, nonreactive stainless steel stands up extremely well to repeat exposure to moisture, steam and acids from cooking.

Its durable chromium oxide finish prevents microscopic damage and deterioration over decades of use.

Cooks who regularly prepare acidic foods benefit from this resilience.

Durability Differences

Reactive stainless steel contains less chromium than nonreactive stainless steel, with more iron instead.

Over years of cooking acidic foods, reactive stainless steel is vulnerable to wear and tear.

The acidic ingredients slowly eat away at the pan’s surface finish.

Deterioration happens on a microscopic scale and may not be visible at first glance.

However, damage does build up over time.

If the protective chromium oxide layer of reactive stainless steel gets more significantly scratched or damaged through daily cooking rigors, the cookware can begin to visibly corrode and pit.

Rust spots may emerge on reactive stainless steel with enough exposure to moisture and food acids.

Nonreactive stainless steel offers maximum durability thanks to its optimized chromium, nickel, and in some cases molybdenum or copper content.

On some nonreactive stainless steel cookware, there may even be additions like titanium and tungsten to further strengthen the molecular structure.

The metals essentially reinforce and protect each other from deterioration.

This makes the cookware exponentially more resilient than reactive varieties in the long run.

Even with daily use and the expected scratches and use-marks that come with it, nonreactive stainless steel stands up beautifully to corrosion and wears extremely well over decades.

Its resilient finish shrugs off moisture, steam and food acids without issue or visible damage accruing substantially over very long periods of time.

For cooks wanting lifelong cookware, nonreactive stainless steel is unmatched.

Cleaning and Care for Both Types

All stainless steel cookware, whether reactive or nonreactive, must be cleaned thoroughly after cooking to prevent surface damage over time.

Food debris, greasy deposits, or acidic remnants should never be left sitting on the surface for long stretches or allowed to bake on through heating cycles.

Stainless steel should be washed by hand or in the dishwasher promptly after cooking.

When washing manually, a non-abrasive sponge or soft cloth should be used with typical dish soap.

Chlorine bleach or other harsh chemicals should never be used, as these can erode the protective finish over time.

Cooks should avoid metal scouring pads, which cause scratching.

Nonreactive stainless steel is considered lower maintenance when it comes to cleaning and care due to its resilient, reinforced composition.

Its extreme durability means scrubs and abrasives are less likely to degrade the surface or cause substantial scratching, pitting or corrosion issues down the road.

With proper prompt cleaning after each use, nonreactive stainless steel beautifully retains its fine mirrored finish for decades of cooking.

Popular Brands Offering Each Type

Well-known brands offering reactive stainless steel cookware lines include Tramontina, Cuisinart Multiclad Pro, Calphalon Tri-Ply, and even some All-Clad tri-ply cookware like the All-Clad D3.

These all blend stainless steel with an aluminum and/or copper core layer sandwiched in the base and sometimes walls.

The multi-ply construction improves heat conduction.

These options represent substantial cost savings over nonreactive varieties.

Leading brands manufacturing nonreactive stainless steel cookware include All-Clad 5-ply, All-Clad D5, Demeyere Proline, Demeyere Industry5, and more premium offerings from Zwilling and Viking.

These brands utilize specialized stainless steel grades with higher nickel and chromium ratios, and no aluminum or copper cores.

The goal is maximum nonreactivity and corrosion resistance.

Of course, there is an elevated price tag attached compared to reactive stainless steel.

Price Differences Between Reactive and Nonreactive

On average, reactive stainless steel cookware is the more budget-friendly option for shoppers.

Well-known brands like Tramontina, KitchenAid and Cuisinart offer quality reactive tri-ply and multi-clad stainless steel cookware lines with aluminum or copper cores to boost conductivity.

A 10 to 12-piece cookware set from one of these brands can readily be found at price points ranging from $200 to $500.

Nonreactive stainless steel cookware is considered an exceptional heirloom-quality investment purchase for serious home cooks.

The ultra-durable construction and specialized metal composition command luxury pricing.

For example, a 10-piece All-Clad D5 Brushed cookware set with lids retails for $1,399.99 directly from the manufacturer.

With proper lifetime care, however, it will serve multiple generations without issue.

More budget-conscious shoppers desiring nonreactivity can explore offerings from brands like Swiss Diamond and Made In, which offer pieces a la carte instead of in huge sets.

While still an investment, purchasing key pans like a fry pan and saucepan individually is less costly than a large cookware set.

Ideal Usage Scenarios: Reactive vs. Nonreactive

Reactive stainless steel is the ideal and most budget-conscious solution for cooks planning less frequent acidic cooking.

Reactive stainless steel works beautifully for more neutral preparation methods like steaming vegetables, making pan sauces, sautéeing meats, preparing stir fries, and more.

Its reactivity will not negatively impact taste or cookware durability with lighter acidic ingredient use.

It provides substantial value and quality at a reasonable price point for many home kitchens.

For cooks planning to regularly cook tomatoes, wines, vinegars, citrus juices, broths and other acidic ingredients, nonreactive stainless steel is viewed as the gold standard.

If preparing tomato-based dishes multiple times per week, reactive stainless steel will gradually corrode and undermine taste.

Only nonreactive delivers nonstop resilience against corrosion and metal leaching over decades of acidic cooking.

It’s the ideal equipment choice for those regularly cooking acidic flavors.

Conclusion

When evaluating stainless steel cookware options, the main differences come down to metal composition, potential reactivity drawbacks, associated durability and price point value.

Reactive stainless steel relies more heavily on iron content, which can leach metals and eventually corrode when cooking acidic recipes frequently.

Nonreactive options like All-Clad D5 minimize iron in favor of more nickel and chromium, preventing metal transfer almost indefinitely.

While reactive stainless steel costs less upfront, nonreactive stainless steel will prove the better lifetime value for serious home cooks thanks to extreme durability and corrosion resistance cooking all recipes.

However, reactive stainless steel offers substantial quality and convenience for those on a budget not regularly tackling acidic dishes.

Carefully evaluate your individual cooking style, budget and desired cookware lifespan before deciding between these two stainless steel categories.

Both have their merits for the right kitchens.