Is scraping Teflon flakes in your family’s pasta a hidden health risk on par with lead paint? Maybe, but stainless steel offers durability without the dangers over lifetime usage.

Stainless steel cookware compares very favorably to Teflon nonstick when weighing criteria like safety, longevity, environmental impact, and effectiveness for diverse cooking tasks.

Let’s dive in to examine Teflon’s risks, stainless steel’s inert properties, cost comparisons, and conclusions to equip your kitchen confidently.

Is Stainless Steel Cookware Safer Than Teflon?

Yes, stainless steel cookware is widely regarded as safer than Teflon nonstick coatings, especially considering long term usage spanning many years.

Stainless steel’s durable, inert properties minimize health risks and eliminate degradation issues associated with Teflon and related plastic polymer coatings.

As we’ll explore more below through comparing toxicity factors, durability, costs, and real-world performance, quality stainless steel cookware sets should be the first choice equipping most home kitchens for daily cooking tasks.

What is Teflon?

Teflon is a trademarked brand name used for the chemical compound polytetrafluoroethylene (PTFE).

PTFE was invented in 1938 by an American chemist named Roy Plunkett, when he accidentally created this new fluorinated plastic polymer.

At the time, Plunkett was working for a company called Kinetic Chemicals, trying to develop new varieties of refrigerants.

Upon checking on stored cylinders of tetrafluoroethylene gas, he discovered that one container had polymerized into a strange waxy white powder rather than remaining a gas.

Further testing revealed the extraordinary properties of this fluorocarbon resin.

After the material was patented and commercialized under the brand name Teflon in 1945, its usage expanded into diverse industrial applications like insulation, semiconductors, and aerospace.

But Teflon became most well-known as a coating for nonstick cookware.

The exceptionally slippery, low friction qualities of a Teflon surface prevented food and liquids from sticking during the cooking process.

However, starting in the early 2000s, concerns began emerging regarding the safety of this popular kitchen product.

Specifically, the chemical PFOA was used for many years during manufacturing of Teflon and other nonstick coatings.

And research started highlighting PFOA’s potential toxicity and correlation with medical issues.

So while Teflon transformed home cooking with convenient, easy-to-clean pans, scrutiny has intensified on the possible health risks of this synthetic coating made with controversial chemicals.

Potential Risks of Teflon

One of the primary chemicals that raised so much concern is PFOA, which stands for perfluorooctanoic acid.

For decades, PFOA was used as a key agent in producing Teflon.

It stabilized monomers during heating and provided durable water, grease, and oil repellency in the finished coating.

However, major scientific studies like research from the U.S. National Toxicology Program and University of Southern California linked PFOA exposure to various adverse health effects.

Conditions associated with elevated PTOA levels included thyroid disease, liver damage, higher cholesterol, decreased fertility, and testicular and kidney cancer.

PFOA is also extremely persistent when it contaminates soil or water supplies, taking many years to break down after release into the environment.

Due to all the emerging toxicity evidence and pressure from health advocates, most companies voluntarily agreed to phase out using PFOA by 2015.

But many consumers remain concerned that residual trace amounts could still be present or that other problematic perfluorinated chemicals are used instead.

So this manufacturing foundation for Teflon leaves lingering questions for cautious buyers.

Beyond PFOA exposure risks during production, additional issues can manifest when Teflon degrades under typical cooking usage.

Extreme heat like preheating an empty pan starts deteriorating Teflon above temperatures around 500° F.

The coating essentially begins decomposing, giving off toxic plastic fumes and particulates.

If inhaled by someone nearby, flu-like symptoms can occur after a condition nicknamed “Teflon flu” or polymer fume fever.

Reported cases mention fever chills, headache, shortness of breath, and severe sore throat following exposure to such overheated nonstick pans.

Furthermore, as Teflon coatings experience long-term wear from metal utensils scratching the surface, tiny flakes or particles of the coating can chip or peel off during cooking or washing.

These flecks may inadvertently get consumed along with food, which raises concerns about what extended exposure from ingesting plastic-based nonstick coating could do to digestive tracts or other internal human biology.

Stainless Steel as an Alternative

Due to all these worries around degradation, ingestion risks, and PFOA-associated toxicity, stainless steel emerged as a compelling alternative.

Rather than relying on a synthetic coating like Teflon, stainless steel cookware is constructed from – as its name implies – stainless steel.

This material is an alloy blend containing mostly steel along chromium, which undergoes an oxidation process to produce stainless steel’s unique properties.

Trace amounts of other metals like nickel, titanium, copper, and molybdenum may also be included.

Chromium gives stainless steel desirable qualities like strength, durability, stain resistance, and a shiny silver luster.

Meanwhile, the steel base provides thermal conductivity for heating up evenly and quickly.

Combined together through smelting and other metallurgy, a stable, inert material forms that is essentially non-reactive when in contact with food during cooking.

So stainless steel does not impart flavors or leach potentially toxic metals or chemicals at concerning dietary levels.

Stainless steel’s high corrosion resistance also means it withstands exposure to heat, moisture, oil, salt, acidity from foods like tomatoes, and other cooking environmental factors.

Pans and pots made from quality stainless steel survive stovetop, oven, or broiler conditions that far exceed temperatures that start degrading Teflon around 500°F.

So even after thousands of hours accumulating extremely high heat, stainless steel remains durable rather than releasing noxious plastic fumes similar to overheated Teflon.

And from a safety perspective regarding consumption, stainless steel earns consistent praise from health-focused government agencies and researchers.

For example, the Alabama Department of Public Health states, “Stainless steels used for food preparation equipment are made from iron mixed with metals that provide corrosion resistance.

The materials used to produce these steels are highly regulated and reviewed for safety.” So credible experts widely regard stainless steel as inert enough for extensive contact with food and drink without posing reasonable risks.

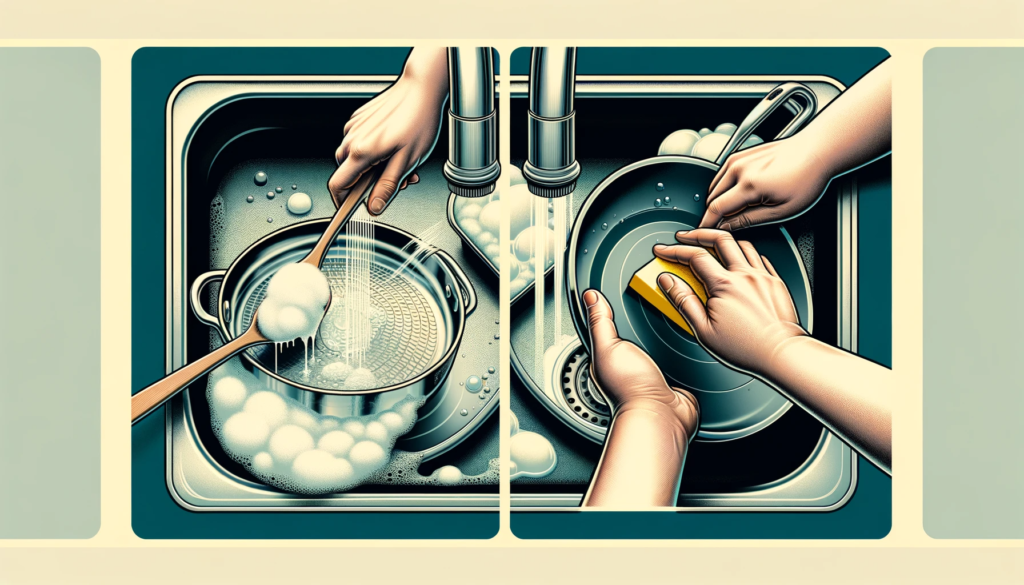

Cleaning and Care Differences

However, while stainless steel offers outstanding durability and chemical/thermal resistance during cooking usage, some gentle care and proper cleaning methods are still required.

Using extremely abrasive scouring pads or tools can gradually scratch the protective surface layer that makes stainless so resilient.

Numerous scrapes, pits, grooves, and smoothing from overly aggressive scrubbing gives bacteria, emulsified oils, and food debris places to stick.

Over many cooking and washing cycles, these stuck-on deposits can carbonize into burnt layers if not removed through gentle cleaning after each use.

In contrast, Teflon demands even more delicate care when washing to avoid ruining the crucial nonstick properties.

Any abrasions slowly destroy the slippery polymer coating as scratches accumulate.

Gradually the surface roughens enough that instead of easily sliding off, food sticks and leaves residue requiring frustrating scrubbing to remove.

Metal cooking utensils like spatulas, spoons, and whisks also easily damage Teflon during routine stirring motions.

The soft polymer finish simply cannot withstand much friction before losing its optimal nonstick abilities.

For both Teflon and stainless steel pans, certain cleaning approaches help maintain proper function by avoiding detrimental abrasion and stuck-on buildup issues.

Using soft-bristled nylon brushes, non-scratch sponges, baking soda solutions, or just boiling water can safely lift residue without scraping or scouring too forcefully.

Gentler scrubbing prevents the microscopic top layer damage that allows oils, carbonized drippings, and other dirt to fuse on permanently.

With careful washing by hand and avoiding harsh dishwasher cycles, Teflon and stainless steel cookware can achieve longer lifespans.

Costs and Performance Comparison

When evaluating the value equation around purchasing stainless steel or Teflon-coated cookware, a few key factors distinguish each option.

Stainless steel pans and pots generally demand a higher upfront sticker price.

Complete cookware sets can range from $200 up to $1000+ depending on brands, material grades, construction quality, and accompanying pieces.

However, that sizable initial investment is offset by exceptional durability spanning decades with proper care.

So based on years of reliable use, stainless steel delivers excellent function for the money.

In contrast, basic Teflon-coated alternatives usually retail for lower prices.

Nonstick skillets, saucepans, stockpots and entire sets often cost under $100.

However, Teflon only maintains optimum nonstick performance for a few years before requiring replacement as coatings deteriorate.

And since Teflon-related health concerns may worry certain home cooks, some brands position “PFOA-Free” labeling as a key selling point to justify slightly higher prices.

But guarantees on chemical formulations and sourcing can be murky.

Evaluating performance also shows some key differences.

Brand new Teflon pans often exhibit exceptional nonstick properties that stainless steel cannot match.

Eggs, crepes, pancakes, and other delicate foods effortlessly slide right off without oil or butter additions needed in freshly purchased Teflon skillets.

However, after moderate usage spanning 1-3 years including some overheating damage and utensil scratches, food sticks annoyingly unless extra fat greases the way.

On the other hand, stainless steel relies more on heat control, oil/butter lubrication, optimal stirring motions, and general cooking experience to prevent excessive sticking or burning.

Developing the necessary techniques and judgment avoids ruining meals and frustrating cleanup in most stainless pans.

Additionally, stainless steel actually improves over time unlike Teflon.

Through repeated heating/cooling cycles, an accumulated layer of baked-on oil residue called “patina” gradually forms.

This slick film then facilitates better food release as years pass.

Health and Environmental Considerations

When examining the broader picture beyond just cooking performance, a few other stainless steel advantages emerge over Teflon coatings.

From a health safety angle, stainless steel’s inert qualities and non-reactive nature in contact with food removes reasonable worries about dangerous toxicity issues.

Boiling acidic tomato sauce for hours or baking casseroles at high oven temperatures simply does not create stainless steel risks comparable to Teflon flu or polymer fume poisoning scenarios.

Stainless steel also avoids environmentally persistent, bioaccumulative chemicals used making Teflon that contaminate water supplies and transfer up food chains.

So both human health and ecological impacts favor stainless steel over years of manufacturing, using, and disposing of accumulated Teflon-coated pans.

And since quality stainless steel lasts practically forever, fewer pans winding up in landfills benefits global resource conservation efforts as well.

Conclusion

In conclusion, weighing all the factors around safety, performance, cost, health impacts, and environmental footprint shows stainless steel as generally the best option when equipping a kitchen with durable cookware built to last through decades of meals.

While Teflon arguably offers minor convenience advantages regarding nonstick properties straight out of the box, too many downsides accumulate over years of use.

Gradually destroying expensive nonstick finishes that demand frequent replacement rarely makes sense for most home cooks after considering stainless steel’s resilience.

And the peace of mind avoiding Teflon-related health risks appeals to many buyers as well.

However, easy-clean Teflon egg skillets may still warrant a supporting role in certain situations.

Dedicated omelet pans and pancake griddles benefit from Teflon’s flawless food release.

For low-fat cooking applications, nonstick coatings save time and frustrations.

But ultimately stainless steel provides the greatest versatility, durability, and safety across diverse everyday cooking tasks.

Once mastering the nuances of stainless steel maintenance and use, its lifetime value clearly outpaces any temporarily helpful but risky Teflon nonstick coatings.