Did you know stainless steel cookware undergoes complex manufacturing processes spanning alloy selection, steel melting, component fabrication and finishing steps before reaching your kitchen?

Creating robust and reliable stainless steel pots and pans entails meticulous quality control across sourcing appropriate steel grades, specialized melting and hot/cold metal working techniques for shaping cookware vessels with excellent cooking properties, followed by finishing operations to impart decorative shine and surface integrity.

Let’s dive deeper into the end-to-end manufacturing system producing stainless steel cookware trusted by home chefs globally.

How is Stainless Steel Cookware Manufactured?

Stainless steel cookware is manufactured through a complex sequence spanning across thoughtful alloy selection, precision steel melting under controlled conditions, fabricating cookware components from steel using processes like welding and metal stamping, applying finishing steps for desired appearance and surface properties, rigorous quality testing, and finally protective packaging for distribution to global markets.

In short, it takes numerous well-orchestrated manufacturing processes to transform raw stainless steel materials into highly functional and durable cookware ready for everyday cooking tasks.

We’ll explore the end-to-end production workflow more deeply throughout this article.

Selecting the Stainless Steel Alloy

The manufacturing of stainless steel cookware starts with the thoughtful selection of the proper stainless steel alloy.

Stainless steels used for making cookware primarily contain iron, chromium, nickel and trace elements like carbon, nitrogen and molybdenum.

The most commonly used stainless steel grades are 304, 316 and 430.

Grade 304 stainless steel contains approximately 18% chromium and 8% nickel in addition to iron.

Grade 316 stainless steel contains an extra 2-3% molybdenum additive to grade 304 composition.

The addition of molybdenum enhances corrosion resistance properties.

Grade 430 stainless steel is mostly iron containing 16% to 18% chromium and minimal nickel.

When selecting the stainless steel grade, cookware manufacturers thoughtfully analyze the desired material properties needed for good performance.

This includes attributes like corrosion resistance, high temperature oxidation resistance, thermal conductivity for even heat spread, durability against denting, coefficients of thermal expansion and fabrication ease.

Alloys with increased chromium and nickel content tend to have better corrosion resistance.

Nickel also enhances ductility which is important during cold forming of steel sheets into complex cookware shapes.

Molybdenum in grade 316 imparts substantial improvement to corrosion performance when exposed to salty or acidic foods during cooking.

High thermal conductivity results in no hotspots allowing uniform cooking of food.

Controlled expansion properties prevent warping or excessive stresses when subjected to high flame temperatures.

Manufacturers also evaluate the machinability and weldability which affect the forming processes.

Additionally, material cost economics comparing relative price differences between grade 304, 316 and 430 stainless steels play a role in the selection.

Using recycled scrap stainless steel as part of the metallic input raw material also assists in cost reduction for large scale manufacturing.

Melting and Refining

Upon selecting the proper stainless steel grade and composition, the manufacturing process moves to the next step of preparing the molten metal bath with the desired chemistry.

The main raw material inputs are iron, chromium, nickel and trace elements.

Iron is derived from iron ore or recycled steel scrap.

The chromium and nickel come from specific ferroalloys, namely ferrochromium containing 50%-70% chromium and ferronickel containing 15%-20% nickel.

Ferromolybdenum can provide molybdenum additive for grade 316 steel production.

The ferroalloys and iron scrap get charged into large capacity electric arc furnaces capable of melting tens of tons of solid metal.

As the solids charge into the furnace, large graphite electrodes energize the furnace initiating an electric arc discharge.

This induces tremendous heating capability of over 1650 degree Celsius from the ionized electric arc allowing complete melting of the charged metals including the high melting ferroalloys.

In addition to electric arc furnaces, other furnace types like induction furnaces, ladle furnaces and converter furnaces also assist in the complex melting and refining stages based on available production capacities and capabilities.

Tight control on the sequential order and amount of scrap, alloy and deoxidizer additions is maintained along with continuous sampling to obtain the desired chemical composition tolerances.

Addition of carbon and nitrogen reactants help drive out oxygen from the molten bath utilizing metallurgical phenomena like deoxidation equilibrium and slag-metal reactions.

This crucial refining step brings down residual trace impurities like sulfur and phosphorus to acceptable levels.

Limestone addition helps form slag layers that segregate and absorb the unwanted impurities into the slag which can be later removed from the molten metal bath surface.

Adding argon or vacuum degassing treatments ensure negligible hydrogen levels critical for preventing embrittlement and porosity flaws in the solid steel.

The refined and rigorously analyzed molten steel bath gets ready for casting into slabs, billets and ingots.

Forming the Steel into Cookware

The molten stainless steel batch gets solidified into large rectangular slabs or round billets by continuous casting processes or into ingots by static ingot casting processes.

Continuous casting allows solidifying poured steel through water cooled copper molds creating endlessly cast slabs saving time and costs compared to older batch ingot casting methods.

Whether slabs from continuous casting or heavy multi-ton steel ingots, the first step in shaping the solid steel stock into stainless steel sheets involves hot working or rolling.

Ingot conditioning through soaking pits allow uniform heat distribution before sending them to the hot strip mill re-heating furnaces.

Slab or plate mills also employ walking beam furnaces to heat up continuous cast slabs for the upcoming hot rolling stage.

In the rolling mill, the heated stainless-steel piece gets passed back and forth between massive rotating steel cylinders termed work rolls that apply extreme downward pressure compressing the metal thinner with each pass while elongating it in the rolling direction.

Special heat resistant steels make up the work rolls.

The gap between the rolls gets progressively narrower to achieve the desired thinness.

Re-rollers convey the strips back to the furnace for re-heating before the next rolling stand gradually transforming thick slabs into thin stainless steel coils.

Intermediate batch annealing between rolling sequence helps restore ductility that work hardening diminishes.

The cold rolling mill further reduces strip thickness accuracy using polished work rolls and higher pressures without re-heating to final gauges under 0.5 mm.

Finishing cold rolling enhances mechanical strength through strain hardening while ensuring surface uniformity and smoothness critical for cookware applications.

Round shaped blanks then get punched from the stainless steel coils/sheets and deeper drawing operations involving steel die stamping and mechanical or hydraulic presses form the circular discs into intended pots, pans and vessels.

Two edges get joined together by fusion welding methods like MIG, TIG or laser welding to acquire the necessary depth after formation.

Finally, handles, lips and attachments get fastened to complete the cookware structure before the final finishing processes.

Surface Finishing

Before packaging and shipment, stainless steel cookware must undergo appropriate surface finishing treatments that enhance appearance while ensuring optimal cooking performance.

The first phase of finishing involves abrasive grinding or linishing designed primarily to remove surface oxides, heat tint scales or weld discolorations accumulated during the prior cookware forming activities.

Belt grinding machines utilize rotating abrasive belts at high surface speed for fast stock removal while tumbling methods apply loose abrasives in barrels providing low-stress surface conditioning.

Robotic grinding systems now enable automated mass finishing.

The next finishing process is polishing which removes thin surface layers transforming dull grey stainless-steel cookware into a shiny mirror-like finish using rotating abrasive wheels made of leather, canvas, cotton or felt material mounted on spindle heads.

It takes off 15 to 25 microns of metal thickness exposing a pristine surface underneath.

Starting from coarse grits like 120 mesh, sequential finer polishing compounds gradually increase the luster and reflectivity.

Final buffing together with abrasive free jewelers rouge compounds attain brilliant polishes through oxide film thinning effects.

This enhances corrosion resistance while lowering surface energies for safe cooking.

The polished surfaces also assist cleaning after cooking besides contributing attractive cosmetic appearance matching premium kitchen aesthetics.

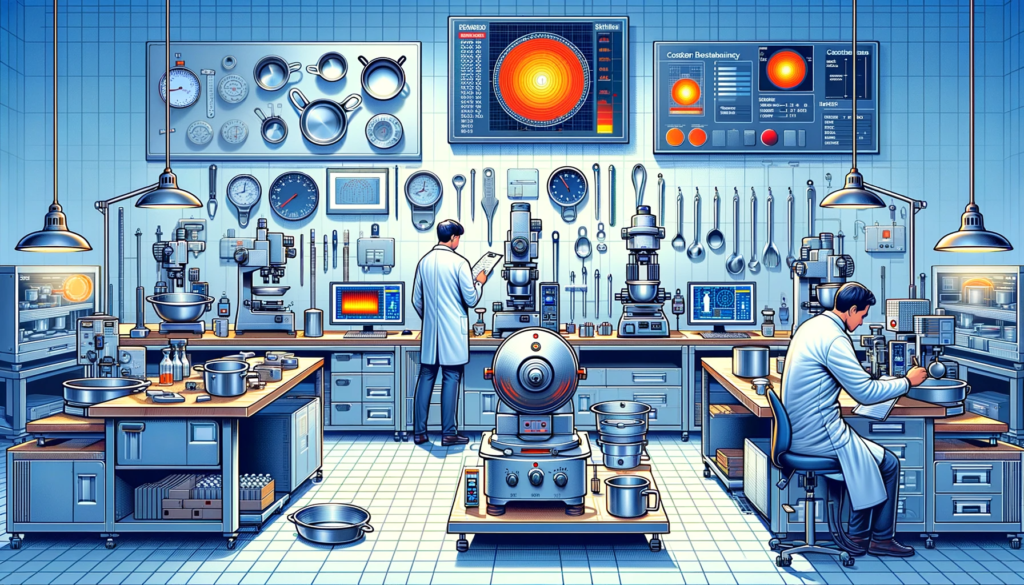

Quality Control and Testing

To guarantee excellence in cooking performance, safety and durability, stainless steel cookware should pass rigorous quality control testing at multiple steps spanning the overall manufacturing sequence before final dispatch.

Following fabrication, dimensional attributes like diameters, depths and thicknesses get measured against design specifications utilizing gauges like micrometers and calipers.

Products undergo meticulous visual inspection for discovering any discernible surface or weld flaws followed by leak and pressure testing to confirm vessel integrity.

Total weights also get checked to ensure uniform metal thickness across the cookware.

In addition, samples from production lots undergo more detailed testing to evaluate key parameters like thermal conductivity, heat distribution patterns, impact resistance, knob adhesion strengths and corrosion resistance when exposed to various food ingredients under heating.

The products must satisfy regional regulatory compliance and safety legislations in target export countries before shipping.

All tests ultimately focus on achieving zero defects ensuring consistent and dependable product quality over long term usage.

Many manufacturers now incorporate automated inspection through computerized laser scanning and machine vision techniques for tracking precision measurements with digital accuracy across production runs.

In some advanced facilities, research laboratories even subject random samples to numerous accelerated life cycle tests to validate robustness simulating years of cookware service lifetimes under simulated harsh operating conditions with rapid heating, thermal shocks and abrasion wear.

Packaging and Shipping

Before protective packaging inside cardboard boxes, the manufactured stainless steel cookware undergoes hot water rinsing or solvent cleaning baths for removing any residual surface films, grease oils or metallic burrs acquired through the multi-stage production workflows.

Customized foam wraps, sleeve covers and separator pads then get applied matching each unique cookware dimensions to prevent contact damage especially for nested cookware sets comprising pots and pans of assorted sizes.

Cardboard spacers placed between stacked items also assist distribution of top-load stresses during transit.

Box labeling contains manufacturing date, production batch number, model specifications and safety advisories to enable tracking and accountability across the supply chain.

Every packaged set undergoes final inspection prior to warehouse storage verification against the assigned bill of materials in the shipping order sheet.

Barcode scanning tracks merchandise identification from warehouse through final delivery.

When customer orders get issued for shipment after sales order processing and invoicing steps, computerized picking lists guide warehouse personnel for fulfilling the right items.

Based on destinations, appropriate sea or air transportation gets selected considering delivery periods and customs formalities.

Consolidated orders then undergo palletization followed by mechanical stretch wrapping to secure the cartons to the wooden pallets preventing in-transit movements.

The palletized merchandise finally transfers into shipping containers destined towards seaports or airports connecting global importers and retail stores who will ultimately make the packaged cookware reach kitchens worldwide.

Precision coordination between material engineers, manufacturing specialists and logistic planners characterizes the integrated business operations achieving mass production and widespread distribution of high-quality stainless steel cookware around the world.

Conclusion

In conclusion, manufacturing high-quality stainless steel cookware requires careful planning and coordination across selecting the optimal steel grades, controlled melting and refining to achieve the desired metallurgical properties, forming sheets into pots and pans, executing multiple finishing steps for safe and efficient cooking performance, rigorous quality testing to ensure durability, and finally global distribution through customized packaging and logistics.

When all these elements come together effectively, the resultant cookware delivers outstanding corrosion resistance, aesthetics and cooking functionality for enriching millions of kitchens worldwide everyday.