Confused about the differences between surgical steel and ordinary stainless steel? As a material choice, each plays vastly different roles across industries.

Surgical steel denotes a niche grade of stainless steel meticulously engineered to exacting standards for medical and biocompatibility requirements.

From composition to manufacturing, it diverges from commercial stainless steel grades designed for more generic uses.

Let’s unpack their granular distinctions across every facet spanning integrity, corrosion resistance, reliability performance and cost.

Surgical Steel vs. Stainless Steel: What’s the Difference?

The key difference lies in the fact that surgical steel denotes a specialized sub-category of stainless steel engineered to more stringently controlled requirements tailored specifically for medical device applications.

While ordinary stainless steel is designed for corrosion resistance across everyday uses, surgical steel is manufactured instead to higher precision standards enhancing properties like biocompatibility, strength, ductility and corrosion performance vital for patient contact items like implants or surgical instruments used in healthcare scenarios.

In a nutshell, surgical steel diverges from broader stainless steel material grades in terms of tightly regulated chemistry inclusions, superior surface finish quality, stringent defect limits and overall sharp focus on elevated metrics around corrosion resistance, mechanical reliability and clinical performance – all of which lend enhanced safety and functionality in sensitive medical uses.

We will explore the finer distinctions between the two types of steel in more granular detail across various factors below.

What is Surgical Steel?

Surgical steel refers to a grade of stainless steel that has been specifically formulated for use in medical applications.

It is made by altering the chemistry of stainless steel to further improve its corrosion resistance, strength, and biocompatibility.

Surgical steels contain elements like chromium, nickel and molybdenum added to iron in precise amounts to enhance its overall physical, chemical and mechanical properties.

The key distinguishing feature of surgical stainless steel is the addition of molybdenum.

Surgical stainless steels typically contain between two to three percent molybdenum in order to boost corrosion resistance.

This allows them to withstand repeated sterilization in harsh environments associated with surgical implants or instruments.

Surgical steels must conform to narrowly defined specifications for composition, grain structure, surface finish, corrosion rate and mechanical properties set by organizations like the American Iron and Steel Institute (AISI) and American Society for Testing and Materials (ASTM).

Common grades used specifically by the medical industry include 316, 316L, 316LVM among others.

The letters ‘L’ and ‘VM’ stand for low carbon and vacuum melted, respectively.

What is Stainless Steel?

Stainless steel refers to a broader range of iron-based alloys containing at least 10.5% chromium.

Unlike other types of steel which rust, stain or corrode easily, stainless steel is highly resistant to moist environments or weathering elements.

The thin chromium oxide layer formed on the surface of stainless steel prevents further corrosion and allows it to be durable.

There are different grades of stainless steel – 304, 430, 410, 303 and 316 being popular examples.

Each type contains varying amounts of important elements like nickel, manganese, carbon or molybdenum added to impart desired traits.

For instance, 304 is the most commercially produced grade known for its good formability and weldability.

Meanwhile, 316 offers improved corrosion and pitting resistance suiting harsher conditions through its molybdenum content.

Thanks to desirable properties like longevity, hygiene and aesthetic appeal, stainless steel enjoys widespread use.

From the large scale realms of construction, infrastructure and transportation to smaller niches in furniture, consumer goods and decor – stainless steel lends versatility across industries.

Differences in Composition

There are minute yet impactful differences in the chemical composition of surgical steel versus stainless steel which set them apart.

Surgical steels have much more controlled and customized alloys.

Surgical grade steel has higher nickel composition ranging from 12-20% instead of 8-10% seen in stainless steel.

Increased nickel enables greater corrosion protection which is vital for reuse and durability of surgical equipment.

Additionally, surgical steel incorporates 2-4% molybdenum rather than 0-3% in standard stainless steel.

Higher molybdenum boosts resistance to pitting and crevice corrosion failure in challenging environments.

It also maintains full corrosion protection in thin sections.

Enhanced levels of chromium (16-18%) in surgical steel instead of 12-15% also boost corrosion performance while improving hardness.

Trace elemental additions of nitrogen, sulfur and selenium offer fine tuning of microstructures and mechanical properties in surgical steel.

Standards mandate lower carbon content – usually less than 0.08% for surgical grade instead of 0.08-1.2% in stainless steel.

This enables better welding characteristics.

Careful control over permissible elemental compositions gives surgial steel greater consistency and reliability over ordinary stainless steel.

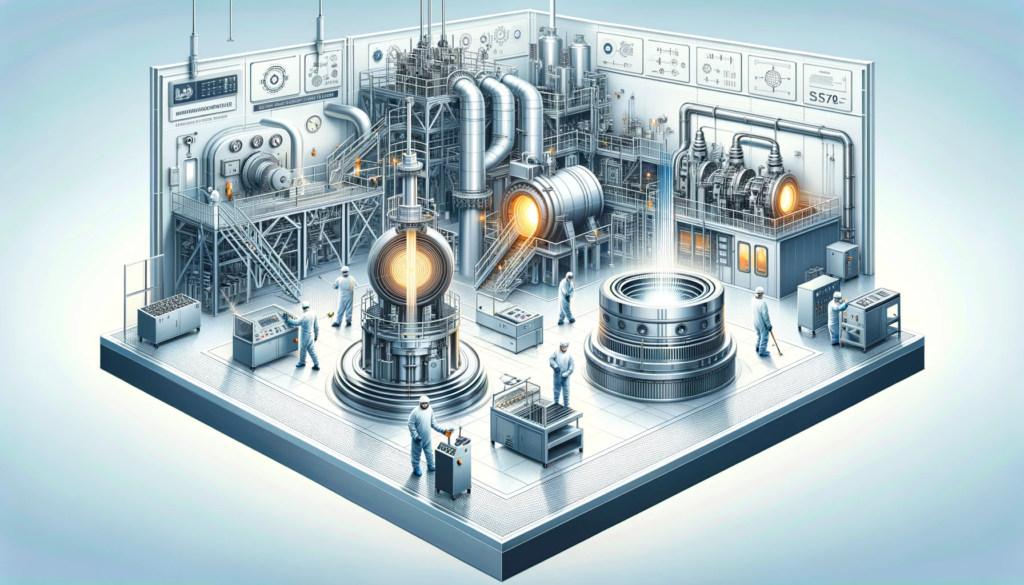

Differences in Manufacturing

Surgical steels are manufactured to stricter protocols to achieve improved cleanliness, surface quality and corrosion resistance.

They undergo specialized remelting techniques like vacuum arc remelting (VAR) or vacuum induction melting (VIM) under controlled conditions to give superior homogeneous metallurgy.

This minimizes defects while removing gases and unwanted elements.

In comparison, commodity stainless steels meant for general purposes adopt faster mass production methods without such refined melting practices.

For surgical steel, critical steps of hot working and heat treatment are likewise monitored vigilantly to realize correct grain sizes and microstructures.

Standards also dictate permissible inclusions or irregularities to avoid compromise in corrosion rate, surface defects or contamination.

Stringent inspection at multiple points using advanced techniques further ensure compliance to specifications in surgical steel.

Manufacturers must submit proof of process validation, equipment qualification and traceability required in surgical steel which is absent in regular stainless steel.

This allows every sequential step – from raw material selection to final finishing operations – to be controlled assiduously in surgical steel.

Its processing demands necessity of skilled quality personnel over automated production.

Differences in Performance

By virtue of significant differences in chemical makeup and manufacturing quality, surgical steel outperforms regular stainless steel when it comes to properties significant for medical usage.

Surgical steel displays much higher corrosion and pitting resistance – over 15 times more – compared to 304 or 316 stainless steel used commonly in industrial or architectural realms.

This allows it to withstand the punishing impacts of repeated sterilization, extreme temperatures and hostile body environments.

Surgical steels better preserve mechanical strength and surface finish integrity over prolonged term implant or tool lifecycles spanning several years or demanding conditions.

The controlled surface quality achieved also lends better cleanliness, reflectivity and polishability making surgical devices more compatible biologically while being easier to inspect for damage visual signs of wear faster.

Enhanced biocompatibility lowers risk of cytotoxic effects.

It also deals better with fatigue failure or brittle fracture thanks to fine tuned metallurgy which gives reliable strength, ductility and fracture toughness necessary in intricate surgical equipment designs.

The superior performance factors translate to unrivaled patient safety.

Cost Differences

Owing to significant investments in specialized manufacturing infrastructure, process rigor, quality systems, traceability paper trail and regulatory overheads – surgical grade steel entails markedly higher cost and lead times over regular stainless steel.

Surgical steels command a premium of 40-100% over comparative stainless steel grades.

Custom certifications, R&D budgets, controlled supply chain logistics further add to expenses which get transferred to end consumers.

Healthcare facilities must factor in this pricier acquisition cost against reuse cycles or lifecycle savings offered by surgical steel while making equipment purchase decisions.

However, minor savings by selecting regular stainless steel can render severe performance compromises affecting patient outcomes or legal liabilities which outweigh upfront cost benefits.

Hence surgical grade steels present better value in long run through their corrosion longevity, resilience to failure risks and ensured biocompatibility.

Their use justifies higher healthcare budgets.

Conclusion

Surgical steel occupies a niche application area distinct from broader stainless steel domains, commanded by its superior surface integrity, long term biocompatibility and reliability performance crucial in medical scenarios with little tolerance for failure.

Manufactured to custom medical material standards via specialized techniques and extensive testing at multiple stages, surgical steel delivers precision alloying, ultra low impurity levels and controlled corrosion properties unmatched by ordinary stainless steels.

Though costlier owing to extensive quality overheads, surgical steels promise value through extraordinary standards of patient safety, equipment longevity and lifecycle savings hallmarking medical grade implementation.